The electrical system is like the lifeblood of a building or factory.

If it is not designed efficiently, it can negatively impact operating costs, safety, and business growth — leading to high electricity bills, frequent power outages, emergency repairs, or premature equipment failure.

By investing in a well-designed electrical system from the start, you can save on long-term costs and achieve your business goals more effectively.

What is electrical system design?

Electrical system design is the process of planning and selecting equipment so that the system operates safely, conserves energy, and supports real-world usage. Key considerations include:

Load Calculation – accurately estimating the electrical load requirements

Equipment Selection – choosing certified and standardized components

Future Expansion – designing with flexibility to accommodate growth

Why should building and factory owners pay attention?

Save 10–20% on electricity costs annually

Reduce the risk of power outages or electrical fires

Support system expansion without major rework

Enhance credibility in terms of standards and safety

Process of Designing an Efficient Electrical System

Accurate Load Calculation – analyze actual power demand with allowances for future needs

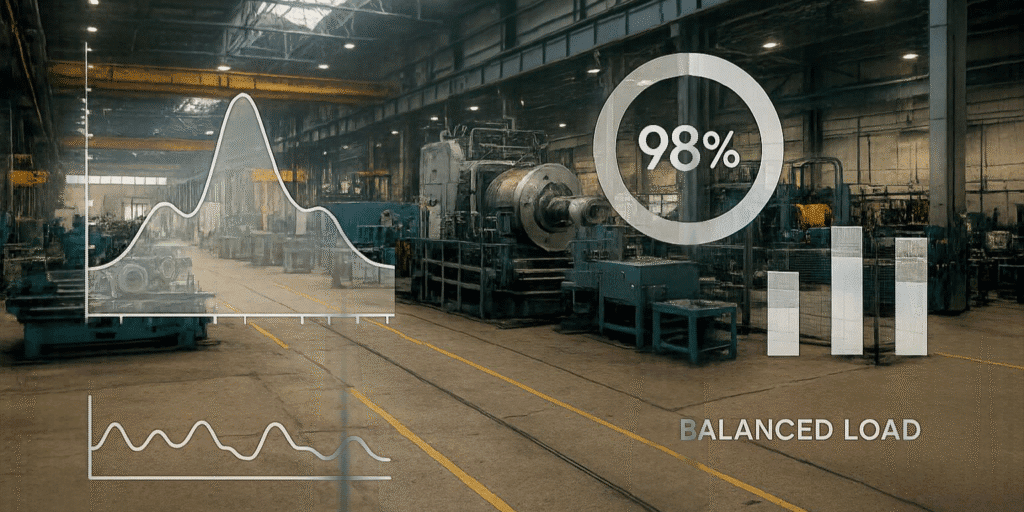

Load Balancing – distribute loads evenly to prevent voltage drops and equipment damage

Standardized Equipment Selection – such as cables, breakers, transformers, and grounding systems

Proper Protection and Grounding Installation – ensure safety and system reliability

Future-Proofing – provide spare conduits, allocate space for new equipment, and integrate smart monitoring systems

Supporting Technologies that Enhance Efficiency

LED Lighting & Smart Illumination Systems – save more than 70% in energy consumption

Capacitor Bank – improve power factor and reduce penalty charges from the utility company

Smart Energy Monitoring / Building Management System (BMS) – track and analyze energy usage in real time

Problems and Hidden Costs of Poor Electrical System Design

Power Factor Penalties – fines charged by the utility company

Abnormal Electricity Bills – caused by unbalanced loads

Repair Costs – for breakers or cables when damage occurs

Rewiring or System Upgrade Costs – required when expanding the system

Examples of Best Practices from Abroad

United States: Uses NFPA 70B, the mandatory standard for preventive maintenance of electrical systems

Europe: Implements the Energy Efficiency Directive (2012/27/EU) to establish a sustainable energy framework

Japan: Requires each factory to appoint a licensed Energy Manager, certified by the government

Practical Tips for Building and Factory Owners

Don’t choose contractors based on price alone — always check their portfolio and licenses

Request a clear Single Line Diagram (SLD) before starting any work

Plan for preventive maintenance from the very beginning

Invest in systems designed for future expansion

Use smart metering for transparency and easier monitoring

Conclusion

A well-designed electrical system for buildings or factories helps business owners save 10–20% on energy costs, reduce the risk of system failures, support future expansion, and enhance safety. With a single investment, you gain long-term benefits.

References

NFPA 70B – Standard for Electrical Equipment Maintenance

Details on preventive electrical system maintenance (Preventive Maintenance) [ edufire.ir ]

Transitioned from a Recommended Practice to a formal Standard in 2023 [ mecojax.com ]

Energy Efficiency Directive (EED 2012/27/EU)

European legal framework on energy efficiency, mandating improvements in energy performance [ wikipedia.org ]