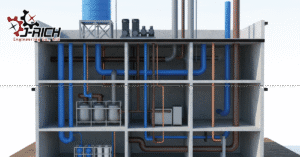

VRV/VRF air-conditioning systems are well suited for buildings that require multi-zone control because they can modulate capacity according to the cooling load of each area. However, when the system fails to cool properly, the temperature does not drop, cooling is inconsistent, or electricity bills rise abnormally, the cause is often not a sudden equipment failure. More commonly, it relates to airflow quality, heat rejection at the outdoor unit, refrigerant charge, and control settings that do not match the building’s actual operating conditions. By checking these factors in a systematic order, you can identify the root cause faster, reduce downtime, and achieve a more cost-effective fix than trial and error.

Overview of the main causes of VRV/VRF poor cooling and high energy use

The poor cooling and high energy use in VRV/VRF systems typically fall into four main categories as follows:

- Insufficient airflow prevents the indoor coil from exchanging heat efficiently, so cooling does not reach the space properly and the system has to run longer.

- Poor heat rejection at the outdoor coil—such as a dirty condenser coil, airflow obstructions, or inadequate clearance around the unit—makes it harder to release heat. This raises the condensing temperature and increases energy consumption. Technical HVAC maintenance references note that dirty coils can significantly reduce cooling capacity and increase power draw.

- Abnormal refrigerant conditions or leaks—such as overcharging, undercharging, or refrigerant leakage—prevent the system from operating as designed and reduce efficiency. NIST research indicates that common issues such as undercharge, overcharge, low airflow, and duct leakage can significantly degrade performance and increase annual energy use.

- Control settings and operation may not match the building’s actual needs—for example, setting the temperature lower than necessary, using an inappropriate operating mode, running schedules that don’t align with occupancy, or unbalanced zone control—causing the system to work harder and run longer than required.

On-site troubleshooting checklist

Symptom 1: Low airflow, slow cooling, and uneven cooling

Common causes

- Dirty or clogged air filters

- Dirty indoor coils restricting airflow

- Malfunctioning indoor unit fan or motor

- Air duct leakage, blockage, or closed dampers

- Airflow obstructions in the space, such as closed air diffusers or newly installed partitions that alter airflow paths

Initial inspection methods

- Check the condition of the air filters and clean or replace them if they are heavily soiled.

- Inspect the airflow at the supply diffusers and compare areas that cool properly with those that do not.

- Check whether any air diffusers are closed or blocked.

- For ducted systems, inspect duct joints and duct runs for leaks, and verify that dampers are operating correctly.

Why does it consume more energy?

When less air passes over the indoor coil, its ability to remove heat from the space is reduced. As a result, the system has to run longer to reach the set temperature, leading to higher electricity consumption. NIST research indicates that low airflow and duct leakage are key factors that reduce system efficiency and increase energy use.

Symptom 2: The system appears to run continuously, but the room does not reach the set temperature and electricity costs are high

Common causes

- Dirty outdoor condenser coils with heavy dust or debris that reduce heat transfer

- Outdoor condenser fan malfunctioning or airflow being obstructed

- Poor installation location for the outdoor unit, with insufficient clearance or inadequate ventilation

- Bent or damaged condenser fins, reducing airflow through the coil

Initial inspection methods

- Visually inspect the outdoor condenser coil. If heavy dirt buildup is present, plan for proper coil cleaning.

- Check for obstructions in front of or behind the outdoor unit that may restrict airflow.

- Verify that the condenser fan operates normally, with no abnormal noise or excessive vibration.

Why does it consume more energy?

When the outdoor condenser coil is dirty, the condensing temperature tends to increase. This reduces cooling capacity and forces the system to use more power. Technical references on HVAC maintenance show that higher condensing temperatures caused by dirty coils can significantly reduce cooling performance while increasing energy consumption.

Symptom 3: Some zones are cool, while others are not, or cooling is uneven

Common causes

- Imbalanced zoning and control, such as some zones being set to very low temperatures while others are set much higher, leading to improper capacity distribution

- Temperature sensors reading inaccurately due to poor installation locations, such as near doors, heat sources, or direct airflow from diffusers

- Certain indoor units experiencing issues with refrigerant flow control components or control devices malfunctioning

- Changes to the occupied space, such as adding partitions, increasing occupancy, or introducing new heat sources, causing the actual cooling load to differ from the original design

Initial inspection methods

- Check the temperature setpoints and operating modes of each zone to ensure they are consistent and appropriate

- Inspect the location of temperature sensors to confirm they are not placed in areas that cause inaccurate readings

- Check for error indicators or abnormal operation of the indoor units in the affected zones, and record the findings to support further diagnosis by service technicians

Symptom 4: Electricity costs increase after air-conditioner cleaning or maintenance

Common causes

- Only the indoor coil was cleaned, while the outdoor condenser coil was not, resulting in restricted heat rejection

- Control settings were changed, such as modified operating schedules, lower temperature setpoints, or inappropriate operating modes

- Refrigerant-related work was incomplete or improper, such as inadequate evacuation or incorrect refrigerant charging

Initial inspection methods

- Review maintenance records to confirm whether refrigerant work was performed and check whether operating data before and after service were documented

- Inspect control settings, particularly operating schedules and modes, to ensure they match actual usage requirements

- If electricity consumption has increased significantly and cooling performance has declined, engage a qualified specialist to evaluate overall system performance in accordance with accepted diagnostic and maintenance practices

Symptom 5: Water leakage, musty odors, and high humidity

Common causes

- Clogged drain pipes, incorrect pipe slope, or kinked drain lines

- Dirty drain pans and accumulated biological growth

- Low airflow causing moisture buildup

Initial inspection methods

- Check whether condensate drains are flowing properly

- Inspect the condition of the drain pan and clean it on a regular basis

- If the issue persists, review the drain piping layout and pipe routing, and also investigate low airflow as a contributing factor

Preventive maintenance approach

To keep VRV / VRF systems operating efficiently and to reduce the risk of rising electricity costs, a structured preventive maintenance program should be implemented as follows:

- Clean air filters regularly and inspect the cleanliness of indoor coils according to the usage schedule.

- Clean outdoor condenser coils and inspect airflow conditions around the outdoor units on a routine basis, as dirty coils directly affect cooling capacity and energy consumption.

- Inspect the condensate drainage system to prevent water leakage and excessive humidity.

- Monitor monthly energy consumption trends together with actual operating patterns to identify abnormalities at an early stage.

- Review control settings such as operating schedules, operating modes, and temperature setpoints to ensure they match the building’s real usage conditions.

- Have refrigerant charge and refrigerant condition checked by qualified specialists, as incorrect refrigerant levels clearly impact system efficiency.

- Perform system inspection, testing, and commissioning in accordance with the design intent, following recognized commissioning practices to ensure the system is properly installed, tested, and operated to meet the building owner’s requirements.

Cases where a specialist should be contacted immediately

- Repeated system faults or warning alarms

- Frequent system shutdowns, or abnormal outdoor unit operation such as fans not rotating or excessive vibration and noise

- Suspected refrigerant leakage or abnormal refrigerant behavior

- Electricity consumption increases significantly together with poor cooling performance, and does not improve after basic cleaning and initial adjustments

Note: Electrical work and tasks involving refrigerants should be carried out by qualified specialists to ensure safety and to prevent further system damage.

Conclusion

Most cases of VRV / VRF systems not cooling properly and consuming excessive electricity are caused by low airflow, restricted heat rejection at the outdoor coil, abnormal refrigerant conditions, and control settings that do not match the building’s actual operating conditions. A systematic inspection approach helps identify root causes more quickly, reduces system downtime, and provides a more cost-effective solution than trial-and-error troubleshooting.

References

National Institute of Standards and Technology, Sensitivity Analysis of Installation Faults on Heat Pump Performance, NIST Technical Note 1848. [nvlpubs.nist.gov]

National Institute of Standards and Technology, Effect of Installation Faults on Air to Air Heat Pump Performance (Summary of key faults such as dirty coils, undercharged refrigerant, overcharged refrigerant, and low airflow). [nist.gov]

NREL, Measure Guideline Air Conditioner Diagnostics, Maintenance, and Replacement (Field data on refrigerant and airflow issues, and recommended diagnostic approaches). [nrel.gov]

Energy.gov.au, Factsheet The Importance of Cleaning Coils (Impact of dirty coils on condensing temperature, cooling capacity, and energy consumption). [energy.gov.au]

U.S. Department of Energy FEMP, HVAC Maintenance and Technologies (Technical guidance and performance impacts of dirty coils and maintenance practices). [energy.gov]

ASHRAE Standard 202, Commissioning Process for Buildings and Systems(Framework for system commissioning and acceptance procedures). [ashrae.org]

ASHRAE, The Strategic Guide to Commissioning (Benefits and best practices for commissioning to meet building owner requirements). [ashrae.org]