When investing in a large air-conditioning system for a building—whether it’s an office, hotel, mall, or industrial facility—the key question is: should you choose a VRV/VRF or a Chiller system?

This article will help you understand the basics, advantages, disadvantages, and conditions that will guide you toward a better decision.

What is a VRV/VRF system?

- VRV stands for Variable Refrigerant Volume, and VRF stands for Variable Refrigerant Flow. The two terms are often used interchangeably. This technology refers to an air-conditioning system that uses refrigerant flowing through pipes to multiple indoor units, with the amount of refrigerant to each unit precisely controlled according to cooling demand.

- A key advantage is its ability to adjust the refrigerant flow rate according to the varying cooling load in each zone (rather than simply switching fully on or off). This allows for greater energy efficiency when certain areas do not require full cooling.

- The VRF system is ideal for buildings with multiple zones, rooms, or floors that may require different temperatures—such as multi-tenant office buildings, hotels, renovated buildings with limited space, and facilities where not all zones operate at full cooling load all the time.

Main limitations of VRV/VRF systems:

- They have limitations in pipe length and vertical height difference — making them less suitable for very tall buildings.

- If the system is too large, it may face reduced efficiency or become less cost-effective to operate.

- Installation and maintenance require skilled professionals with specific expertise in VRV/VRF systems.

What is a Chiller system?

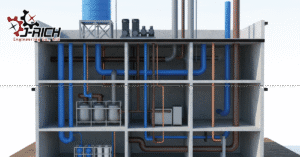

- A Chiller system produces chilled water at a central unit and circulates it through pipes to indoor equipment such as AHUs (Air Handling Units) or FCUs (Fan Coil Units), where the chilled water absorbs heat from the air to provide cooling throughout the building.

- The chilled water that has absorbed heat then flows back to the chiller unit to be cooled again, completing a continuous cooling cycle.

- This system typically includes additional components such as water pumps, cooling towers, valves, control systems, and large piping networks.

Chiller systems are suitable for buildings with a high and continuous cooling load, such as shopping malls, factories, large hotels, high-rise office buildings, and expansive open spaces.

Main limitations of Chiller systems:

- High installation cost due to the large number of components involved.

- Requires significant space for equipment rooms, cooling towers, and large air or water ducts.

- Maintenance involves multiple aspects, including water quality management, cleaning, pump servicing, and valve maintenance.

Comparison Table: VRV/VRF System vs. Chiller System

| Aspect | VRV/VRF System | Chiller System |

|---|---|---|

| Cooling Method | Uses refrigerant flowing from outdoor units to indoor units in each zone. Compressor speed and refrigerant flow are adjusted according to actual load. | Produces chilled water from a central unit and circulates it through pipes to AHUs/FCUs for heat exchange, delivering cool air to the space. |

| Suitable Building Type | Office buildings, hotels, medium-sized facilities, or areas where all zones are not used simultaneously. | Large buildings, shopping malls, factories, hospitals, or facilities with high continuous cooling load. |

| Installation Cost | Moderate cost, easier to install — no cooling tower or chilled-water system required. | High cost — requires central chillers, water pumps, piping, and additional installation space. |

| Operating Cost | Energy-efficient during partial load; unused zones can be turned off to save energy. | More cost-effective when operated continuously at full capacity, such as in malls or factories. |

| Temperature Control | Highly flexible — temperature can be controlled independently by zone or room. | Controlled in large zones; individual room control requires additional FCU/VAV installation. |

| Maintenance | Simple — no water system; regular coil cleaning and system checks are sufficient. | More complex — requires water treatment, pump maintenance, cooling tower cleaning, and monitoring of water quality. |

| Space Requirement | Compact and flexible piping layout — suitable for buildings with limited space. | Requires a mechanical room, cooling tower area, and large duct/piping space. |

| Lifespan | Approximately 10–15 years with regular maintenance. | Approximately 20–30 years — ideal for large-scale buildings with long-term operation. |

Comparison Table of Advantages and Disadvantages: VRV/VRF System vs. Chiller System

| System | Advantages | Limitations |

|---|---|---|

| VRV/VRF |

• Energy-efficient during partial load operation • Independent temperature control for each zone or room • Requires less installation space, no large machine room • Direct refrigerant system — operates quietly • Flexible installation, ideal for buildings with limited space • Easy maintenance — no water or chemical treatment needed |

• Not suitable for very large buildings or continuous high load • Limited refrigerant pipe length and height difference • Failure of main outdoor unit can affect multiple zones • High repair cost in case of refrigerant leakage • Requires specialized technicians for installation and maintenance |

| Chiller |

• Supports high cooling loads — ideal for large buildings • Long lifespan (20–30 years) • Stable operation under continuous use • Provides better air and humidity control (via AHU) • Suitable for centralized cooling systems |

• Very high initial installation cost • Requires large space (machine room, cooling tower, large piping) • Needs on-site maintenance team for water quality and pumps • Inefficient when operating under partial load • More complex and costly maintenance than VRF |

How to Choose the Right System for Your Building

If you’re deciding between a VRV/VRF system and a Chiller system, consider the following key factors carefully to help you make a choice that’s as close to the right answer as possible.

- Building Size and Cooling Capacity

- If your building is not very large (for example, with a total cooling load of around ≤ 500 TR), a VRV/VRF system usually provides an excellent balance of efficiency and cost-effectiveness.

- However, for larger buildings or those with high, continuous cooling demand, a Chiller system tends to be more economical in the long run.

- Building Usage Pattern

- If your building has zones that are not used all the time or areas that are turned on and off alternately, a VRV/VRF system is more suitable because it allows independent zone control.

- In contrast, if the building operates full-time with high and steady loads, the Chiller system offers greater stability and performance.

- Installation Budget and Long-Term Cost

- If you need to minimize upfront installation costs, a VRV/VRF system is a smart option—it requires less equipment and space.

- But when considering long-term value, especially for large-scale buildings, a Chiller system may be more cost-effective thanks to its longer lifespan and higher overall efficiency.

- Temperature and Air Quality Requirements

- If your building requires precise temperature control and enhanced air quality—for instance, air filtration or humidity control—a Chiller system combined with AHUs (Air Handling Units) clearly has the advantage.

- Building Structure and Installation Space

- Ensure that your building has enough space for a mechanical room, cooling tower, chilled water piping, and air ducts.

- If space is limited, the VRV/VRF system is more convenient, as it doesn’t require a large mechanical room and offers flexible piping layouts.

- Maintenance Team and After-Sales Support

- A VRV/VRF system is generally easier to maintain and only needs periodic checkups, making it ideal for buildings without a dedicated maintenance team.

- However, if you have an in-house engineering or technical team, a Chiller system can be efficiently maintained and optimized for long-term performance.

- Hybrid System Design

- Some buildings choose a hybrid approach for maximum flexibility—for example, using Chillers in zones with constant high loads, and VRV/VRF systems in office areas or guestrooms to reduce costs and improve energy control.

This hybrid configuration is even recommended by major manufacturers like LG for large-scale, mixed-use projects.

- Some buildings choose a hybrid approach for maximum flexibility—for example, using Chillers in zones with constant high loads, and VRV/VRF systems in office areas or guestrooms to reduce costs and improve energy control.

References

- ASHRAE Handbook – HVAC Systems and Equipment, 2021 Edition.

- ASHRAE Standard 15 & 34 – Safety Standard for Refrigeration Systems.

- NFPA 90A – Standard for the Installation of Air-Conditioning and Ventilating Systems (2024).

- LEED v4.1 – Building Design and Construction Guidelines, U.S. Green Building Council (USGBC).

- LG HVAC Blog – Chiller or VRF? The Ultimate Debate. [ lg.com ]

- Energy Efficiency Comparison of VRF and Chiller Systems. – ScienceDirect (Elsevier), 2022.

- Performance Evaluation of Variable Refrigerant Flow (VRF) Systems. – ResearchGate, 2021.

- Cooling Load Analysis for Chilled Water Systems. – Engineering Toolbox, 2020.